|

|

|

|

|

|

|

|

|

|

|

Enter Data for Calculations Below

|

|

| |

|

|

|

|

|

End Mill Diameter*

|

Number of Cutting Edges*

|

Radial Width of Cut*

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To complete calculations, enter known data into

the empty boxes on the left hand side below.

All mandatory fields for calculations are indicated by (*). All calculations are based on industry

formulas and are intended to provide theoretical values. Actual results could vary and SGS Tool

Company assumes no responsibility. |

|

|

|

|

|

|

|

|

Surface Feet per Minute

|

Solution

|

|

|

Revolutions per

Minute*

|

Constant

|

End Mill Diameter

|

Surface

Feet per Minute

|

|

|

|

|

|

|

|

|

SFM

|

|

|

|

|

|

|

|

|

|

|

|

Revolutions per Minute

|

Solution

|

|

|

Surface Feet per

Minute

|

Constant

|

End Mill

Diameter

|

Revolutions per Minute

|

|

|

|

|

|

|

|

|

RPM

|

|

|

|

|

|

|

|

|

|

|

|

Inches per Minute

|

Solution

|

|

|

Inches per Tooth (Chipload)

|

Revolutions per Minute

|

Cutting Edges

|

Inches per

Minute

|

|

|

|

|

|

|

|

|

IPM

|

|

|

|

|

|

|

|

|

|

|

|

Inches per Tooth (Chipload)

|

Solution

|

|

|

Inches per Minute*

|

Revolutions per Minute

|

Cutting Edges

|

Inches per

Tooth (Chipload)

|

|

|

|

|

|

|

|

|

IPT

|

|

|

|

|

|

|

|

|

|

|

|

Inches per Revolution

|

Solution

|

|

|

Inches per Minute

|

Revolutions per Minute

|

|

Inches per

Revolution

|

|

|

|

|

|

|

|

|

IPR

|

|

|

|

|

|

|

|

|

Inches per Tooth (Chipload) to Obtain Theoretical Surface

Finish

|

Solution

|

|

|

Desired Surface

Finish Ra (microinch)

|

End Mill Diameter

|

|

Inches per

Tooth (Chipload)

|

|

|

|

|

|

|

|

|

|

IPT

|

|

The actual finish is usually rougher than

theoretical calculation.

Other factors

not calculated help to ultimatley determine finish.

|

Approximated Parameter

|

|

|

|

|

|

|

Radial Chip Thinning Feed Calculator

|

Solution

|

|

|

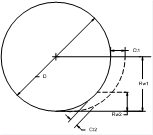

Whenever the radial width is less than half the tool diameter

(as in Rw2) the chip thickness is less than the feed per tooth and additional

feed is possible using the chip thinning calculation.

|

|

Inches per

Tooth with Thinning

|

|

|

|

|

|

|

IPT

|

|

|

|

|

This new Inches per Tooth has been optimized for the Depth of

Cut

|

|

|

|

|

|

|

|

|

Optimized

Inches per Minute

|

|

|

|

|

|

|

IPM

|

|

|

|

|

This is the new Feddrate using

the optimized Inches per Tooth above

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

Programmed Feedrate for Interpolating a Bore

|

Solution

|

|

|

|

|

When moving in a circular motion, the actual feed rate at the

outside diameter differes from the programmed feed rate. Use the feed rate below when boring out a

large bore, the centerline feed rate is calculated and inserted into program

to compensate for the motion.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

Diameter of Bore

|

IPM at Diameter

|

End Mill Diameter

|

Inches per

Minute at Centerline

|

|

|

|

|

|

|

|

|

IPM

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Programmed Feedrate for Interpolating a Boss

|

Solution

|

|

|

|

When moving in a circular motion, the actual feed rate at the

outside diameter differes from the programmed feed rate. Use the feed rate below when boring out a

large bore, the centerline feed rate is calculated and inserted into program

to compensate for the motion.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

Diameter of Boss

|

IPM at Diameter

|

End Mill Diameter

|

Inches per

Minute at Centerline

|

|

|

|

|

|

|

|

|

IPM

|

|

|

|

|

|

|

|

|

|

|

|

|