|

|

|

|

|

|

|

|

|

|

|

|

|

Enter Data for Calculations Below

|

|

| |

|

|

|

|

|

End Mill Diameter*

|

|

Number of

Cutting Edges*

|

Axial Depth of Cut*

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To complete calculations, enter known data into

the empty boxes on the left hand side below.

All mandatory fields for calculations are indicated by (*). All calculations are based on industry

formulas and are intended to provide theoretical values. Actual results could vary and SGS Tool

Company assumes no responsibility. |

|

|

|

|

Surface Feet per Minute

|

Solution

|

|

|

Revolutions per

Minute*

|

Constant

|

End Mill Diameter

|

Surface Feet

per Minute

|

|

|

|

|

|

|

|

|

SFM

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Revolutions per Minute

|

Solution

|

|

|

Surface Feet per

Minute

|

Constant

|

End Mill Diameter

|

Revolutions

per Minute

|

|

|

|

|

|

|

|

|

RPM

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inches per Minute

|

Solution

|

|

|

Inches per Tooth

(Chipload)

|

Revolutions per Minute

|

Cutting

Edges

|

Inches per Minute

|

|

|

|

|

|

|

|

|

IPM

|

|

|

|

|

|

|

|

|

|

|

|

Inches per Tooth (Chipload)

|

Solution

|

|

|

Inches per Minute*

|

Revolutions per Minute

|

Cutting

Edges

|

Inches per Tooth (Chipload)

|

|

|

|

|

|

|

|

|

IPT

|

|

|

|

|

|

|

|

|

|

|

|

Inches per Revolution

|

Solution

|

|

|

Inches per Tooth

(Chipload)

|

|

Cutting

Edges

|

Inches per Revolution

|

|

|

|

|

|

|

|

IPR

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

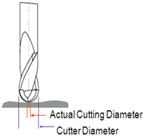

Actual Working Diameter Parameter Adjustment

|

Solution

|

|

| |

|

When machining at axial depths less that 1/2 the radius of the

cutting tool, the actual diameter engaged in the cut changes and your

parameters must be adjusted. The

Effective Cutting Diameter engaged must be used for the calculations.

|

Effective

Cutting Diameter

|

|

|

|

|

|

Deff

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

Revolutions

per Minute for Deff

|

|

| |

|

|

|

RPM

|

|

| |

|

This new Spindle Speed has been

optimized for the Effective Cutting Diameter |

|

| |

|

|

|

|

|

Fractional Axial Chip Thinning Feed Calculator

|

Solution

|

|

| |

|

Whenever the axial depth is less than half the tool diameter (as

in Ad2) the chip thickness is less than the feed per tooth and additional

feed is possible using the chip thinning calculation. The Effective Diameter (Deff) must be used

to properly calculate.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inches per

Minute w/ Thinning

|

|

|

|

|

|

IPM

|

|

|

|

This new Feedrate has been

optimized for the Depth of Cut

|

|

|

|

|

|

|

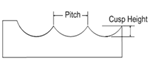

Surface Finish Calculator

|

Solution

|

|

| |

|

Cusp Height gives an idea of Surface Finish and is most accurate

when applied to a flat surface.By reducing the Pitch of Step Over distance,

Cusp Height is reduced and a finer finish is produced.If a desired Cusp

Height is known, the appropriate Pitch can be calculated.

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

Enter the Pitch

(Step Over) to Calculate Cusp Height*

|

Cusp Height

|

|

|

|

|

|

|

|

Inches

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter Cusp Height

to Calculate Pitch (Step Over)*

|

Pitch (Step

Over)

|

|

|

|

|

|

|

|

Inches

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|